***Christmas Countdown 160 days***

"Seeing a piece of furniture take shape, it is like watching a child grow."

Pen blanks .. Ebay Listings

Wood Movement Effects Explained

We can also make 'pens' and 'wooden bowls' on our lathe.

Made from all sorts of different woods and plastics.

(which come in different colors/designs).

The stains we prefer use are " MinWax ®" brand stain,

there you can see the differant colors available.

We are a family owned and operated business.

We make custom made wood furniture/cabinets made and designed to your specifications.

We will build furniture/cabinets to fit your small or large spaces.

Variety of woods ranging from pine, oak, walnut, cherry

Specializing in antique reproductions...

examples .. piesafe, drysink, jelly cabinet

All solid wood construction and features cabinet grade veneer plywood, where it is needed.

There is absolutely 'NO' particle board used in the furniture we make.

The lumber we use is cut from Indiana trees into lumber on site.

The lumber is then air dried for about 30-40 days outside covered up.

Then put into one of two solar drying kilns, from there the drying time 45-60 days (depending on the weather).

Ideally for making furniture the moiture content should be around 6-8% moisture content for a stable piece of furniture/cabinet ...

(all wooden piece will "move" with a change in temp or humidity.)

The following pictures are a sample of what we do, aside from the custom work.

If a image fails to load, right click in the corner then it will load.

|

|

|

|

|

|

If you need a certain size of a cutting board ..

please contact us know of your idea and/or what woods you have in mind .. we can ship

If you wish, you can hit reload and see different pictures.

|

We also do custom sawing. If you have logs or barn timbers that you would like to have cut into lumber, email for estimate, if you want it dried, that will be a extra fee. |

Re-sawing-Moldings-Planing. If your wanting lumber resawed or made into moldings or just looking for your lumber to be planed down, email for a estimate. |

|

What we offer is the following wood species in lumber sales. Rough sawn Oak, Walnut, Cherry, Pine, and several other species You can find the email links below. |

Prices vary per species. All lumber will be for Kiln Dried, Rough Cut Lumber. Please email for prices and availablity. Our lumber is random length and width. Most stock is 7/8" thick after drying. |

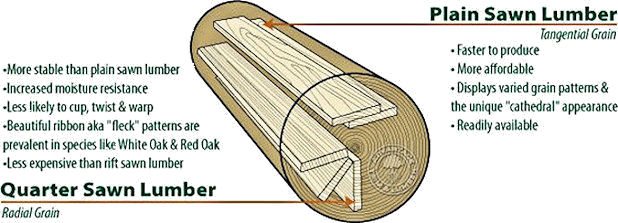

| Q. What is quartersawn lumber? A. Technically, quartersawn lumber has the growth rings of the tree approximately perpendicular to the board's broad face. In contrast, plain sawn lumber has the growth rings parallel to the board's broad face. Quartersawn produces both quartered and rift lumber. |

Q. How is quartersawn lumber achieved? A. There is only one true way to quarter saw a log and we do it this way. First, we cut a log into quarters. Each quarter is then processed by cutting a single board off one face, then cutting the next board from the opposite face, and cutting from alternating faces until the quarter is completely cut. | Q. What are the aesthetic qualities of quartersawn lumber? A. The most notable characteristic of quartersawn lumber lies in its incomparable grain patterns. Also depends on the log and the grain in the wood. Medullary ray fleck, wavy grain and interlocked grain are all visually enhanced when the log is quartersawn. The revival of Mission style furniture is just one example of how today's artisans are rediscovering the unique beauty of quartersawn lumber.Today's heirloom furniture, the antiques of tomorrow, is crafted from quartersawn lumber. Quality reproductions and renovations of artisans' work demand true quartersawn lumber. Quartersawn wood is the choice of wood artisans. |

Q. What are the structural qualities of quartersawn lumber? A. Quartersawn lumber is the uncontested winner when compared to plain (or flat) sawn lumber.

|

Q. What's the difference between quartered and rift lumber? A. A quartered board features medullary ray or "fleck" perpendicular to a grain, which typically forms angles from 60 degrees to 90 degrees with the board?s surface. A rift board exhibits a clean, straight, vertical grain pattern, which typically forms angles from 30 to 60 degrees with the board's surface. |

Q. If quarter sawing is so good, why don't all sawmills do it? A. For most, the art of quarter sawing has been lost over the years. Like many superior practices of the past, quarter sawing lost favor to plain sawing techniques. Plain sawing is easier, cheaper and quicker ? but it results in more waste, less grain characteristic and less stable lumber. |

|

Q. How we saw for best grade of lumber out of a log? A. Opening cuts are done with the bark still on/off the log We then take a 6" opening slab cut on the worst face off the log. then we turn log 180 degrees..and take a 6" opening cut in that face. then we take a number of 1" boards off that face and then turn log 90 degrees, and open that face with a 6" slab cut... then take a number of boards off that face until the grade of the lumber goes down. Then we turn to last face, open it up with a 6" cut. If the face shows good, take a number of boards off it until the grade goes down. Continue sawing the best face and turning the log to saw the best face possible. Any boards needing edging are edged after the log is sawed. Some need both sides edged, some will only need one edge....some might not need any edging. Usually the center of the log is the lowest grade of lumber. This is called the 'heart' wood and it might contain bugs, ants, rot, knots, etc. |

Calculate the weight of your logs if you wish.

|  |

General

Sawyer questions..

Sawyer

Visitor Count: 4675

|

all images are owned by the webmaster, do not copy or share. |

|||||

Updated 02-19-2025